Hayden Pattullo: Digital Fabrication for Contemporary Material Specificity

A new conceptual basis upon which to focus the contemporary use and problem spaces of digital design tools in architecture, to address modern problems of material and object durability

STATUS

Completed

KEYWORDS

MEDes

Digital fabrication

Architectural design

Additive manufacturing

Material optimization

Circular economy

SUPERVISOR

Joshua Taron

ACKNOWLEDGEMENTS

Joshua Taron, Kristen Forward, Oluwaseyi Arole, Kasper Guldager-Jensen, Sara Camagni, Morten Lund, Robert Claiborne, Matthew Parker, Jason Johnson, Guy Gardner, Alexis Handford

The modernist model of “logical positivism” that emerged in the early-20th century

Modernist movement placed the onus of design squarely within the material world. This movement attempted to replace the immaterial “metaphysical” approach to design and material with physically-provable absolute concepts of materiality. However, this model failed to recognize that the value and use life of modern material is highly contingent on distributed and imperceptible immaterial systems such as supply chains and reverse logistics that function beyond immediate scales of space and time (scales that are classically the territory single buildings and products). Approaching the design of buildings and objects through this constrained scalar lens has produced a significant amount of waste via inefficient object lives and perpetuated the logical positivist model of design through the wide misuse of current digital design tools.

Contemporary notions of material specificity, such as DeLanda’s “possibility space” and McDonough and Braungart’s Circular Economy, attempt to reject logical positivism by identifying the contingent factors, or “events,” across a material’s life that must be designed for, such as its flexibility between uses and adaptability within the supply chain. Through a series of literature reviews, case study analyses, and experiments, this thesis will demonstrate the waste problems associated with logical positivism in modern design, describe the Circular Economy as a new form of event-scale for the design of materials, and posit how contemporary digital tools may be instrumentalized for material design at these new event-scales. Ultimately, this work constructs a new conceptual framework of event-scale thinking for material, which promotes different and less wasteful applications of digital tools in design and production.

Linear and Distributed Models of Object Durability

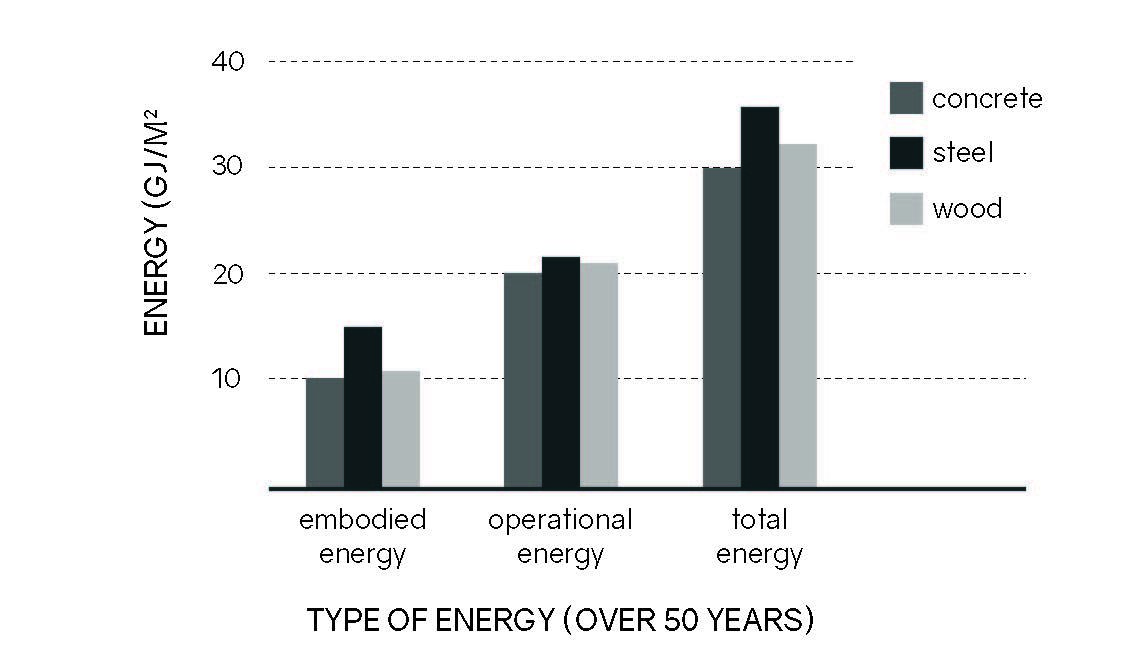

Embodied Energy

Reasons for building demolition

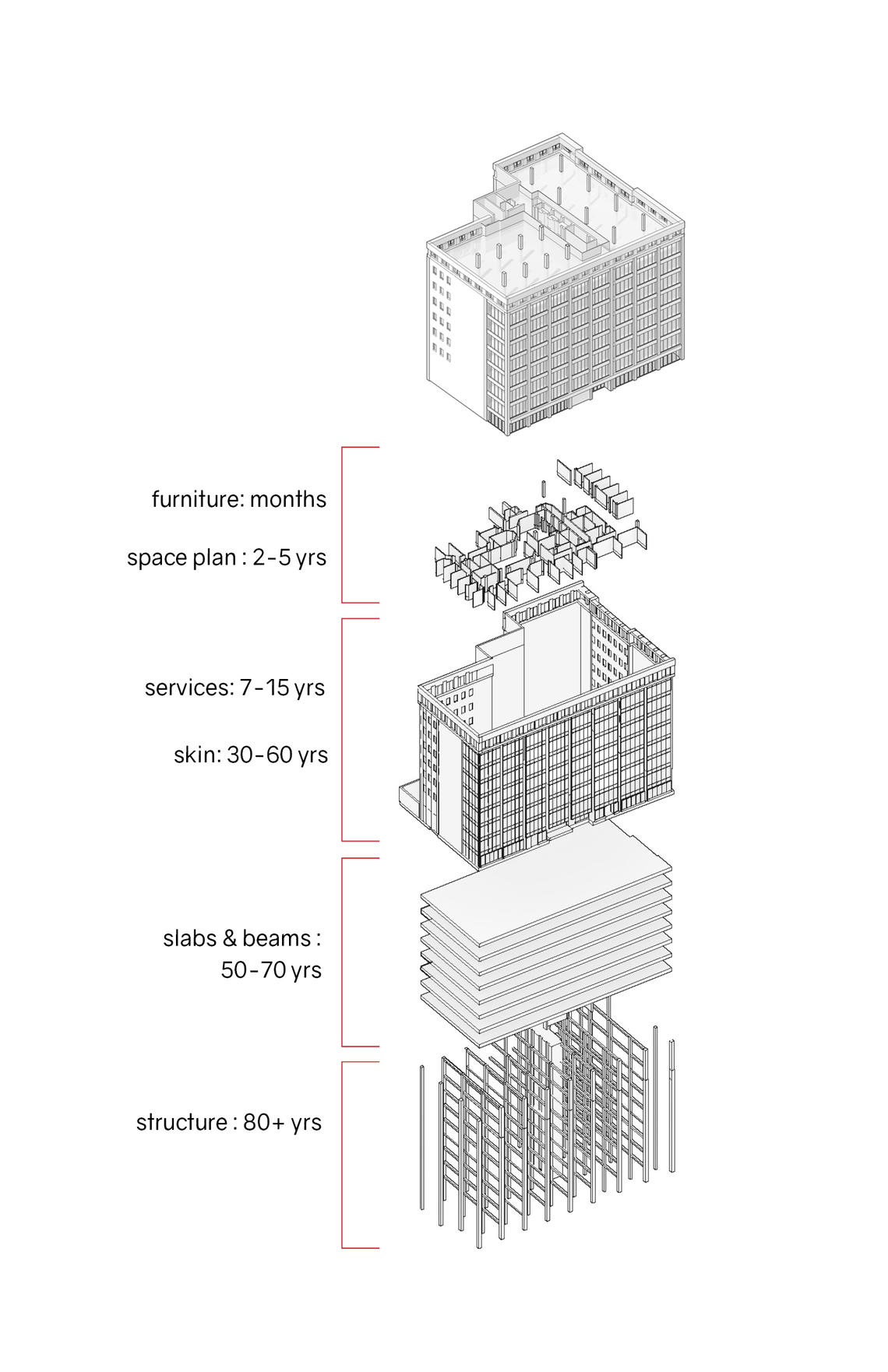

Building Layers

Building layer environmental impact

Building lifespans

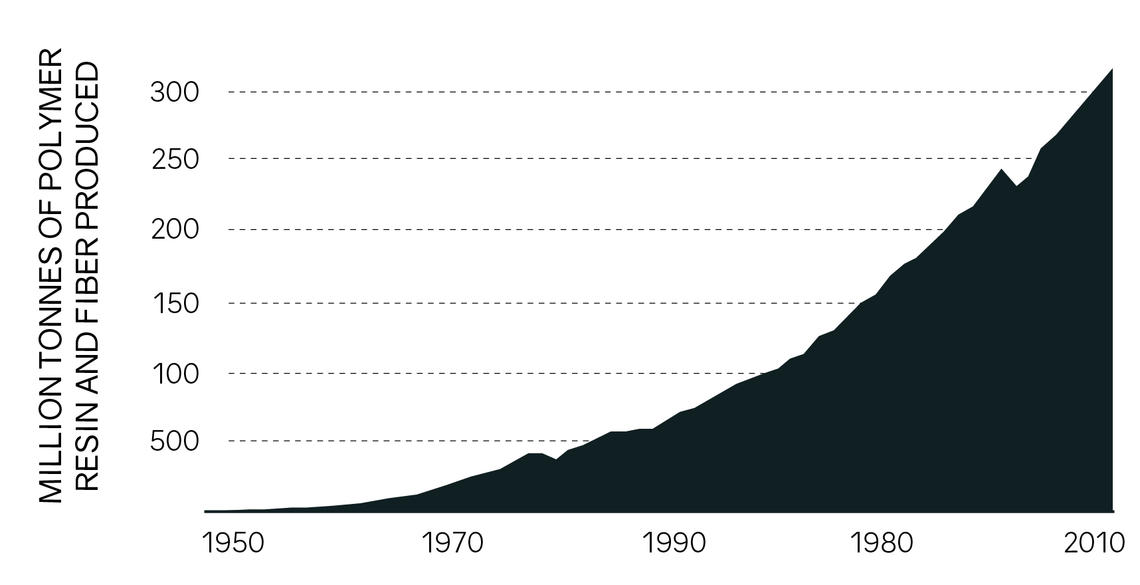

The rapid increase in plastic production since its popularization as a consumer material in the 1950s (reinterpretation of a diagram by Geyer et al, 2017)

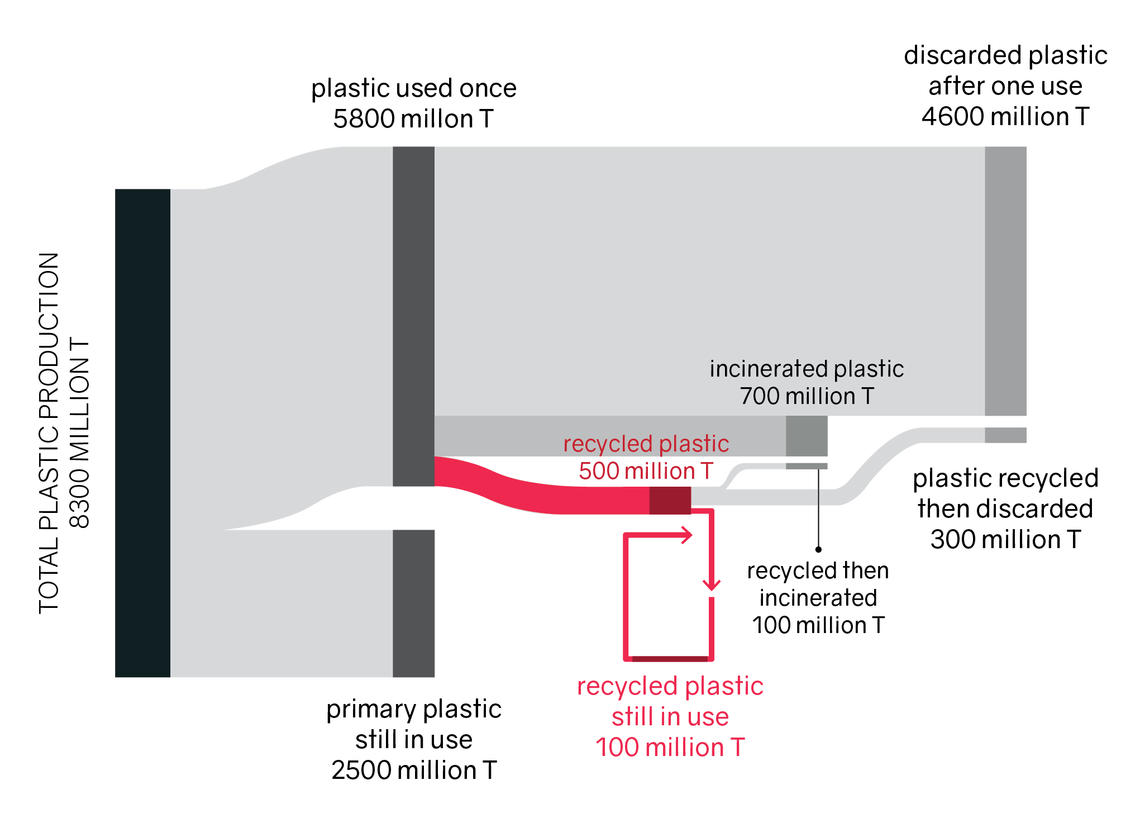

A map showing the life of all plastic ever produced, measured in million tonnes (reinterpretation of a diagram by Geyer et al, 2017)

Personality Perceptions about Homeowners Plotted in Three-Dimensional Space (reinterpretation of a diagram by Sadalla and Sheets, 1993)

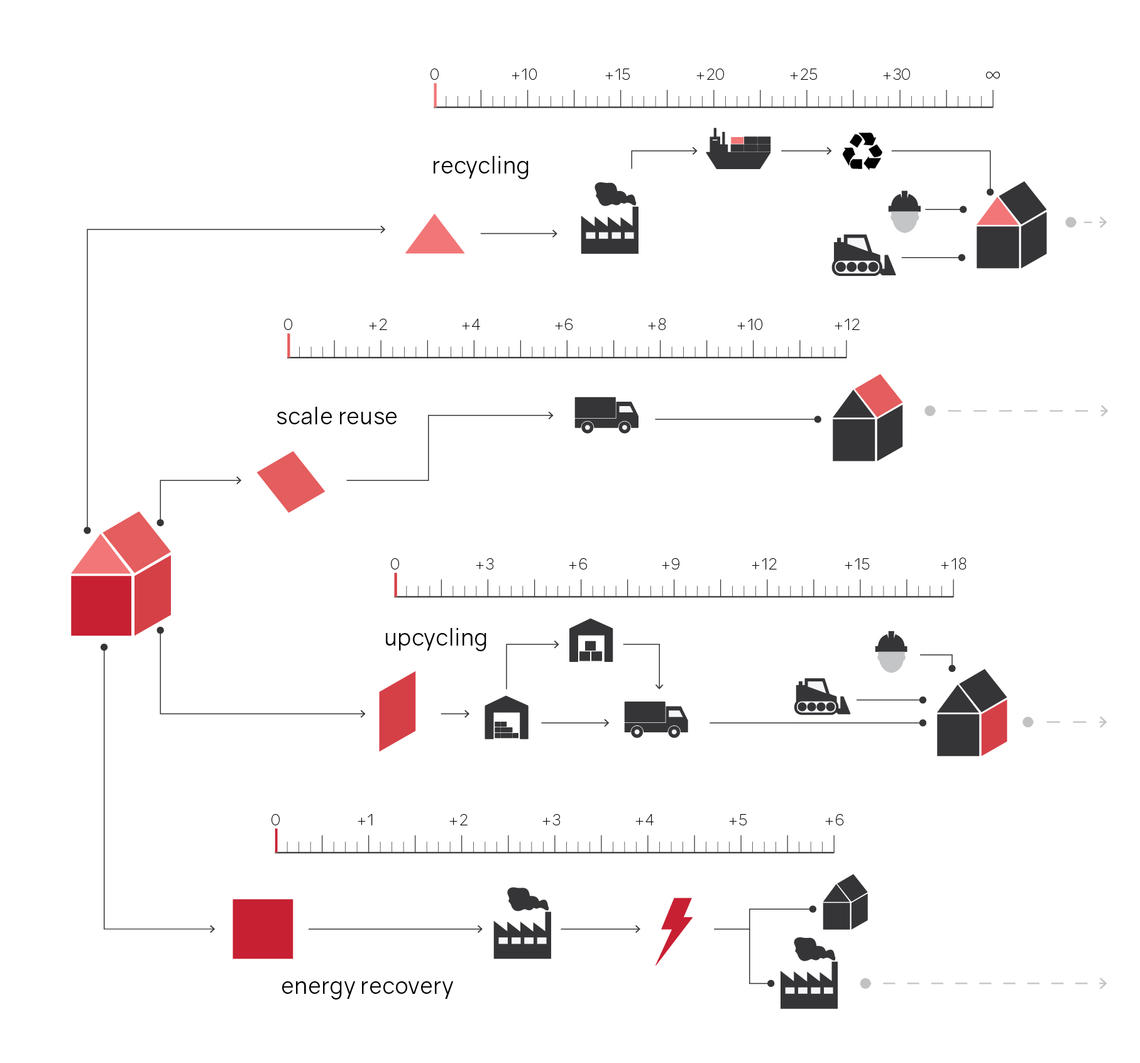

Contemporary Design Event Scales and the Circular Economy

A map of the possible technical and biological reuse cycles at the end of a material’s life (reinterpretation of a diagram by the Ellen MacArthur Foundation, “Growth Within,” 2015)

The process of standard construction logistics, in which material, labour, and equipment converge within a specific location and timeframe to produce a building

The process of reverse logistics, where management of materials, labour, and equipment is based upon distributed, non-localized demands for the material’s use in subsequent applications, rather than the localized demands of the building

Standard linear material life model, where objects are designed, produced, and disposed of. In this model, the building separates feedback loops in its production (design, build cost, etc) and feedback loops in its disposal (disassembly cost, waste management, etc)

A more modern material life model, in which materials may be recovered from an end-of-life object, processed, and utilized in the production of subsequent objects

A contemporary circular material life model. Most importantly, this model involves collaboration between design and waste management (in the “Material Reuse Feedback Loop”) in order to sync challenges and opportunities between material beginning and end-of-life. Secondarily, demolition costs are factored into project costs, providing a feedback to initial design, and material tracking allows for end-of-life owners to receive feedback from the building’s beginning-of-life on how to best maintain, remove, and/or reuse materials (in the “Building End-of-Life Feedback Loop”)

The expected lifespans of different building layers for a 1970s-era downtown Calgary office building (Guldager-Jensen et al, 2019)

The Designing Out Waste proposed concrete panel refabrication facility (Guldager-Jensen et al, 2019)

Design Objects for Contemporary Distributed Permanence

The material complexity required for a square profile panel from the ELH facade

Compared metrics for a number of single panel geometries printed using standard AM methods

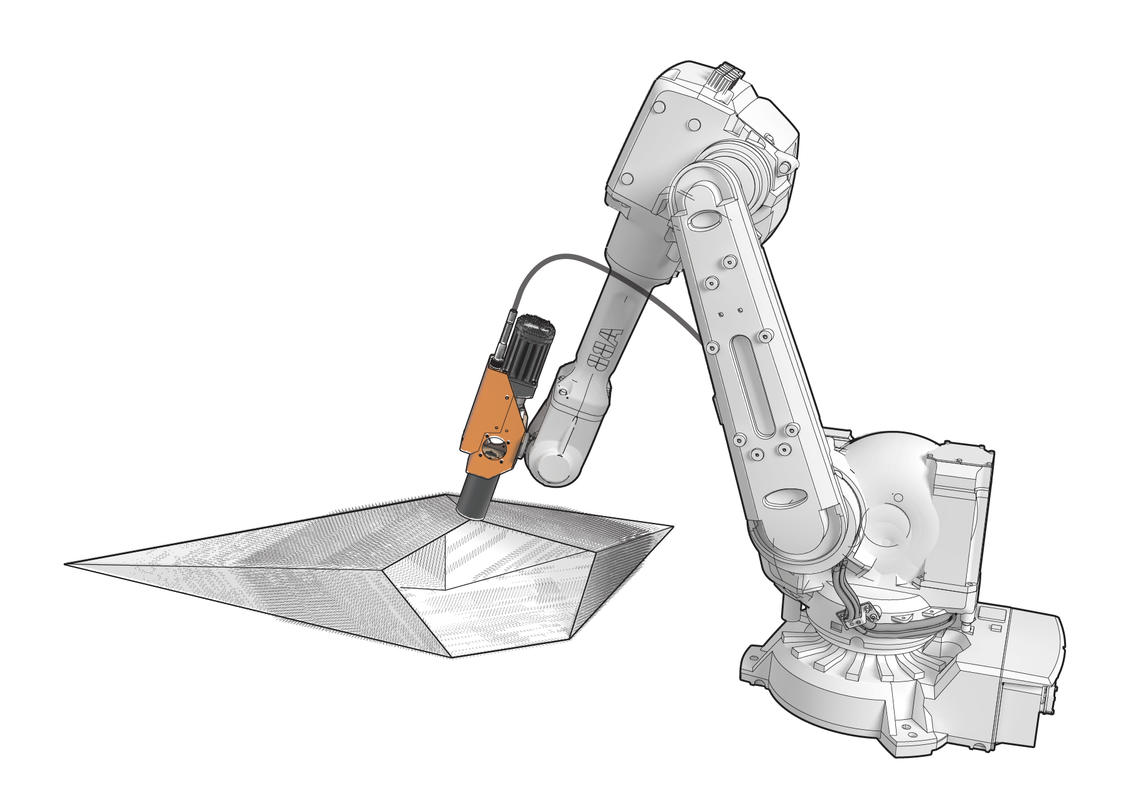

Control and connection overview for the robotic AM equipment setup